Proscenium Opening Protection via Smoke Control

As most everyone involved in the design of performance spaces knows, IBC 2018, 410.2.4 states that stages with a height greater than 50 feet require separation between the stage and seating area by a 2-hour fire-resistant, proscenium wall. The opening through which the audience views the stage is required to be protected as outlined in Paragraph 410.2.5.

There are several stage opening protection options offered in 410.2.5. A fire safety curtain complying with NFPA 80, Chapter 20, horizontal sliding doors complying with International Building Code (IBC) 2018, Section 716, an approved water curtain complying with IBC 2018 Section 903.3.1.1, a smoke control system complying with IBC 2018, Section 909, or, “… natural ventilation designed to maintain the smoke level not less than six feet (1829 mm) above the floor of the means of egress.”

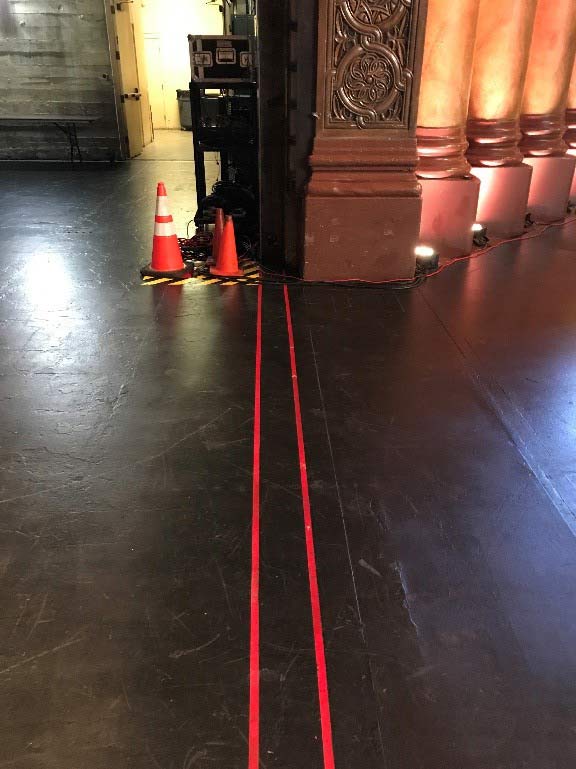

Fire line under a fire safety curtain. Sacramento Memorial Auditorium, Sacramento, CA. Nothing should be placed in this zone which might prevent the fire safety curtain from closing. Photo by Chip Ulich, ASTC.

The most common of these options is the fire safety curtain. Curtains that protect openings over 850 square feet must be motorized. Large openings may require framed curtains to resist air pressure differentials, adding to the cost and complexity of the system. The area directly beneath the fire safety curtain (the fire line) must always remain clear to allow the curtain to seal to the stage floor in case of emergency deployment. This poses problems for band and orchestra layouts, and scenic designs that often extend through the proscenium opening and onto the apron. The fire line is a 6-inch to 12-inch clear path below the fire safety curtain, which can interrupt the music ensemble or scenery. More often, the fire line is ignored and items such as pianos, chairs, music stands, or scenery are placed in the path of the fire safety curtain. These items will block the full deployment of the fire safety curtain, negating its effectiveness.

Alternative methods of proscenium opening protection include horizontal sliding doors and water curtains. Sliding doors have rarely been used in the United States. Water curtains, aka deluge curtains, have seen moderate use, sometimes with disastrous results from accidental deployment. The remaining option, a relative newcomer to proscenium opening protection, is smoke control.

While smoke control had been an alternative to stage house roof vents in IBC 2006, 410.3.7.1, smoke control as an alternative method of proscenium opening protection was not added to the IBC until 2009. Only a few facilities have since been constructed using this protection method. This could be due to the 2008 economic downturn when many projects were delayed or cancelled. Or perhaps the code addition has gone unnoticed. Eleven years later, several theatres are now coming online using smoke control for proscenium opening protection. Smoke control also remains as an alternative to stage house roof vents as indicated in IBC 2018, 410.2.7.

Roof ducts for Smoke Control, McKnight Center for the Performing Arts, Stillwater, OK. Fire protection engineering: Cosentini Associates, New York. Photo by Chip Ulich, ASTC.

In order to use smoke control per IBC 2018, 410.2.5, the facility must not utilize provisions of smoke protected assembly seating, and the proscenium opening smoke protection system must comply with Section 909: Smoke Control Systems.

Some of the salient features and requirements of Section 909 are that the smoke control system is intended for the protection of occupants, not contents. Smoke must remain at least six feet above the highest level of egress for a minimum of 20 minutes, the system must be engineered in accordance with generally accepted and established engineering principals, and the system must be documented with information and analysis that demonstrates compliance.

In addition to the IBC requirements, NFPA 92: Standard for Smoke Control Systems, applies to the design, installation, acceptance testing, operation, and ongoing periodic testing of these systems. The requirements of NFPA 92 include makeup air, which can be introduced through open doors, windows or vents. Air movement can be provided by fans or openings to the outside. Makeup air supply needs to be below the smoke layer and air velocity limitations apply in certain situations. Makeup air cannot cause the required door-opening force to exceed allowable limits. In large spaces where stratification of smoke may occur, a detection scheme must be utilized.

A smoke control fan and exhaust vent, McKnight Center for the Performing Arts, Stillwater, OK. Fire protection engineering: Cosentini Associates, New York. Photo by Chip Ulich, ASTC.

The code allows for various methods of design calculations, each with their own parameters. The fire protection engineer can use algebraic equations as a means of calculating individual factors used to establish smoke control system requirements. Scale modeling is another method available as is computational fluid dynamics (CFD) modeling.

Acceptance testing is another requirement of NFPA 92. The system must be tested against the design criteria to confirm the criteria has been achieved. The testing procedures are to be outlined in the design documents along with pass/fail criteria. Acceptance testing must demonstrate the final integrated system installation complies with the design and is functioning properly. Prior to testing, all building equipment must be in its normal operating mode, even equipment not used as part of the smoke control system. Testing needs to be conducted on both normal and standby power, if provided. The system test sequence must demonstrate the system sequencing from normal mode, to smoke control mode for first alarm, transfer to standby power if provided, and return to normal mode. Additional test and measuring requirements are outlined in Chapter 8.

Periodic testing is an ongoing responsibility of the owner. Chapter 8 requires proper maintenance of the system that shall, as a minimum, include the periodic testing of all equipment, such as initiating devices, fans, dampers, controls, doors, and windows, to ensure the system is maintained according to the manufacturer’s recommendations. Dedicated systems (those not sharing equipment with other systems, such as building HVAC devices) must be tested at least semiannually. Non-dedicated systems (those sharing equipment used by other systems such as building HVAC) are to be tested at least annually. Periodic tests must determine the airflow quantities and the pressure differences across smoke barrier openings, at the air makeup supplies, and at the smoke exhaust equipment. All test results are to be documented in the system operations and maintenance logs. Any modifications made to the system must be tested and documented as well.

There are several considerations to be made before selecting this protection method. First, costs of equipment such as fans, controls, ducts and dampers, smoke detection systems, and design team and third-party reviewer fees must be factored. Additional considerations include the ongoing testing requirements, education of facility personnel on system functionality, and the interface with the local fire department. Keep in mind that some of the construction costs are offset by the elimination of the fire safety curtain and roof vents.

A smoke control vent at stage house roof, McKnight Center for the Performing Arts, Stillwater, OK. Fire protection engineering: Cosentini Associates, New York. Photo by Chip Ulich, ASTC.

While the design, maintenance, and testing requirements may appear complex, the resulting functionality this option provides to the theatre may be worth it. The stage performance is no longer constrained by this unseen piece of building equipment called a fire safety curtain. Scenic designers are free to push the design downstage of the proscenium opening bringing the production closer to the audience. Orchestras and choirs can get closer to the audience and not have to worry about code compliance by placing equipment outside of the fire line. This increases intimacy and may result in better sound quality by placing the musicians within the same acoustic environment as the audience. In short, smoke control systems provide theatre artists better flexibility and functionality in their pursuit of presenting the best performance possible.

This article is derived from a panel presentation at the USITT Conference and Stage Expo, March 14-17, 2018, in Fort Lauderdale, FL. Panel participants included Lisa Osborne, PE, President, Collaborative Engineering Group, Houston TX; Julie Brown, PE, Senior Fire Protection Engineer, Associate Director, Jensen Hughes, Westminster, CO; Kimberly Oates, ASTC, Principal, Schuler Shook, Dallas, TX; Chip Ulich, ASTC, Senior Theatre Consultant, Schuler Shook, San Francisco Bay Area, CA.

By Chip Ulich, ASTC

Disclaimer: Any views or opinions expressed in this article are solely those of the author and do not necessarily represent those of the American Society of Theatre Consultants. This article is for general information only and should not be substituted for specific advice from a Theatre Consultant, Code Consultant, or Design Professional, and may not be suitable for all situations nor in all locations.