Rigging Terminations – Then and Now

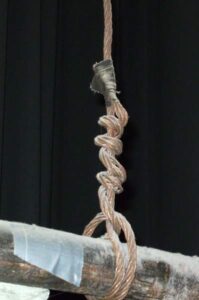

A recent observation made by an ASTC member noted that in a recent industry publication an advertisement included an image of wire rope lift line terminations consisting of a clove hitch around a pipe batten held in place by three cable clips. This observation became a topic of some discussion among members on ASTC’s internal email group. Member comments included “I was always taught that this method went out of style with Peter Clark…” [a well-known and respected rigging contractor long out of business] and “NO NO NO!”

Certainly, this method of attaching a wire rope lift line to a stage rigging pipe batten fell out of favor a long time ago. While it is sometimes still seen in much older systems installed up until the early 1970s (typically in K-12 schools), no self-respecting stage rigging system designer would specify this type of termination today. Stage rigging loads are typically much heavier than they were 50 years ago, and the advent of high speed, motorized hoisting systems have increased the dynamic forces on lifting media exponentially.

But is this type of stage rigging lift line termination inherently “unsafe?” After all, it was common in smaller, older systems. In most consultant’s experience with stage rigging systems, a failure of this kind of termination method (in fact, of almost any termination method) is exceedingly rare. Would this old-school method hold up to today’s standards?

ANSI E1.4-1, the current industry standard for Manual Counterweight Rigging Systems, voluntarily developed by ESTA’s Technical Standards Program (TSP), has been in existence for well over 10 years. ASTC members participated in this (any many other) standards creation process(es). In the latest edition approved by ANSI in October of 2022, Section 3.3 Lift Line Connections, there are a substantial number of requirements, covering everything from batten clamps, trim chains, and trim-adjustment batten clamps, to bridle connections and even fiber (manila and synthetic) rope terminations.

So, what does the current standard say about using a wire rope clove hitch around a pipe batten, held in place by three cable clips?

Absolutely nothing.

Boiled down to its essence, the standard simply requires (as stated in the first part of Section 3.3) “Lift lines shall be connected at both ends using rated hardware designed for the connection, or using methods approved for use with the lifting media.” This is a performance requirement, based on such factors as loads, materials and methods used, the intended application, and manufacturers’ recommendations. The section does include some prescriptive requirements for certain components (like the use of forged steel or ductile materials), but otherwise it simply details how lifting media terminations or batten connection methods must perform.

Over the years, manufacturers, systems designers, and installers have developed “industry and good installation practices” that, for example, provides a safe and secure method of terminating 1/4” and 3/16” galvanized 7×19 wire rope, the lifting media most commonly seen in today’s manual and motorized stage rigging systems. This method uses a properly sized cable thimble and a single, swaged copper compression fitting, which develops 100% of the breaking strength of the wire rope. Using an 8:1 design factor, a termination for 1/4” galvanized 7×19 wire rope is good for a working load limit of 875 pounds, which exceeds most stage rigging manufacturers’ rating for a common single line, 8” diameter loft block.

Now let’s consider the clove hitch method shown in the advertising image that was being discussed [but not included here]. There’s actually a lot of information missing in the image. What is the diameter of the wire rope? What type of wire rope is it exactly? What is its breaking strength and acceptable bending ratio? What is the diameter of the pipe batten? Are the cable clips drop forged or malleable?

Even if we assume worst case factors, this type of termination may be perfectly acceptable depending on the load. A “napkin” calculation could indicate a working load limit as high as 400 pounds in a static condition. This would certainly be acceptable for very low load conditions, like dead hanging a fabric banner. But it would not be acceptable for a stage rigging lineset lifting a 1,000 lbs. or more.As consultants and designers of stage rigging systems, we have some inherent and preconceived notions about what is “acceptable” when specifying and evaluating lifting media terminations, with the cable thimble and a swaged fitting method being the most common. This meets the ANSI standard and holds up to an engineer’s scrutiny when they “do the math.” However, an alternative component design or method should not be simply dismissed out of hand without looking carefully at the application for which it has been designed and confirming if it is appropriate. ANSI E1.4-1 is essentially a safety standard, and because it is mostly performance based and not entirely prescriptive, it is an excellent guide in helping to make that (de)termination.

By Peter Scheu, ASTC

Disclaimer: Any views or opinions expressed in this article are solely those of the author and do not necessarily represent those of the American Society of Theatre Consultants. This article is for general information only and should not be substituted for specific advice from a Theatre Consultant, Code Consultant, or Design Professional, and may not be suitable for all situations nor in all locations.